INDUSTRIAL APPLICATIONS:

Process Temperature Maintenance

Precision Matters: Maintaining Process Temperatures

While freeze protection is critical for preventing ice-related damage, process temperature maintenance is equally important for industrial applications that require precise thermal control at temperatures above the freezing point of water. Many industries rely on consistent temperatures to ensure efficiency, safety, and product integrity.

Why Is Process Temperature Maintenance Important?

Ensures Product Quality

Precise temperature control prevents degradation and inconsistency in sensitive industries like food, pharma, and chemicals.

Prevents Solidification

Fluids stay flowable by avoiding thickening or freezing that can disrupt industrial processes.

Protects Equipment

Heat prevents blockages and damage caused by crystallized or gelled materials in pipes and tanks.

Boosts Energy Efficiency

Stable temperatures reduce the need for reheating and minimise process-related waste.

Prevents Condensation & Corrosion

Prevents moisture buildup inside pipes that can lead to rust and system failure.

Supports Safety & Compliance

Reliable thermal control helps meet safety standards and environmental regulations.

Prevent costly issues with process temperature protection.

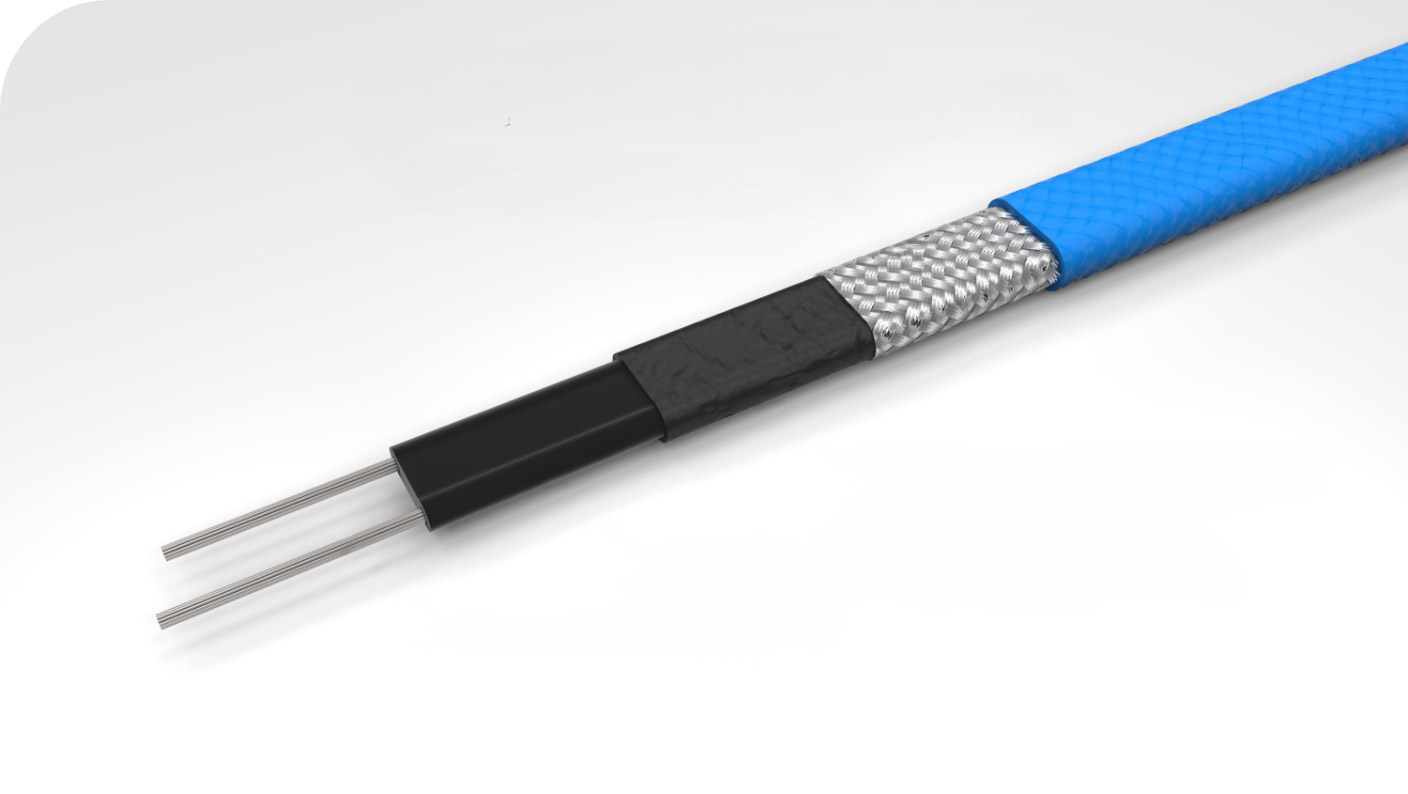

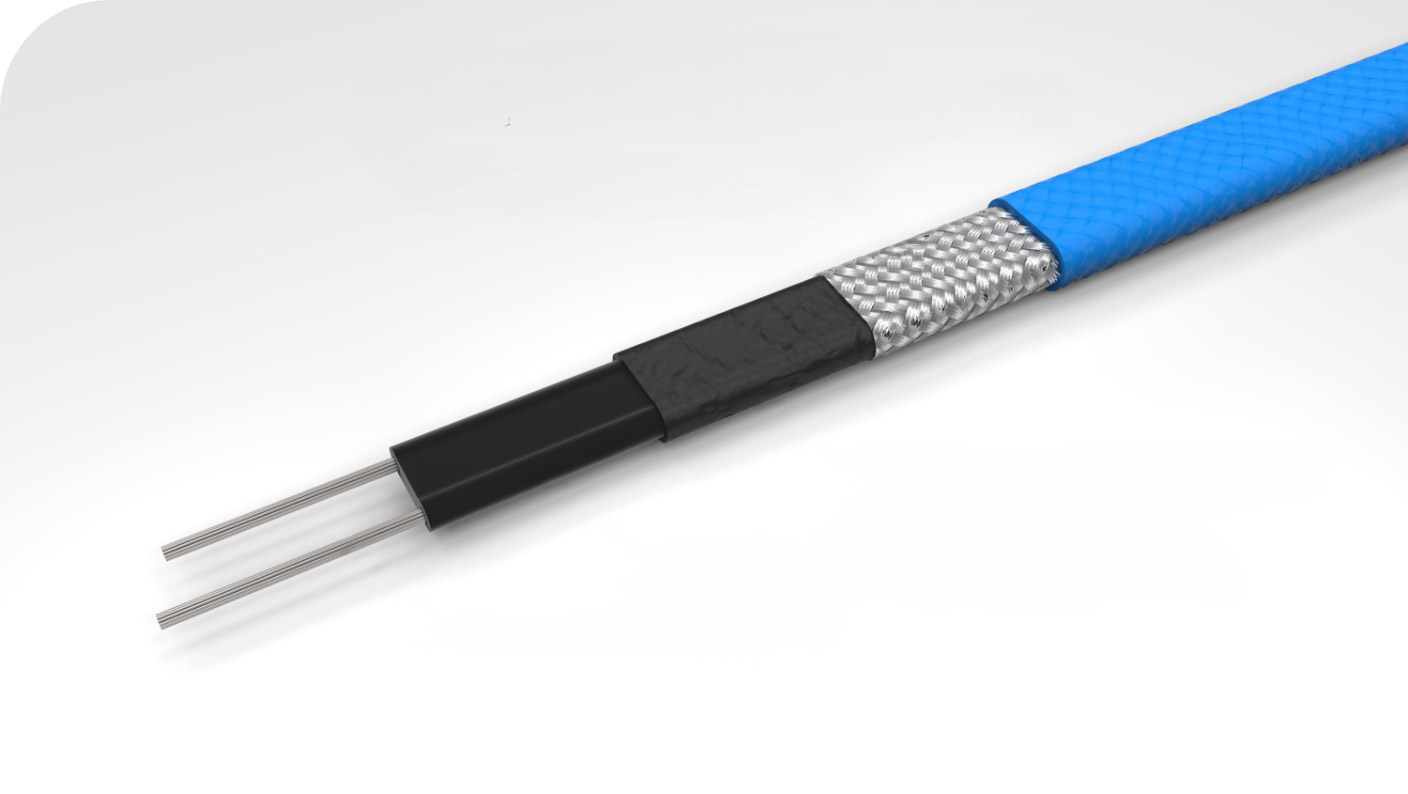

Drexan PipeGuard: Reliable Heat Tracing for Process Temperature Maintenance

Maintaining stable temperatures above freezing is essential for efficiency, safety, and product quality across many industries. Drexan’s PipeGuard Self-Regulating cables offer accurate heat output, exceptional durability, and the longest lifespan on the market.

Key Benefits:

- Built for hazardous and non-hazardous

environments - Resists corrosion from harsh chemicals

- Certified for CSA (CUS) for North America.

- Installs on metal and non-metal pipes, tanks, and vessels

- Backed by the industry’s best warranty

Note: Hazardous locations are defined by the CEC Section 18 and NEC as areas with risk of fire or explosion due to flammable gases, vapours, or dust. Refer to current codes for full compliance details.

Related Resources

Zone Information Guide for a complete list of hazardous locations

Download NEMA ratings for a complete list of enclosure types

Design Worksheet to choose the right trace heating system

Related Products

Trace Heating Cables

Need trace heating? We offer reliable, innovative solutions for freeze protection and temperature maintenance, with precise -0/+10% wattage tolerances.

AMIGA

Our family of high-profile components for installation with Drexan’s Self-Regulating Heating Cables.

Mechanical Thermostats

Thermostats ideal for applications where freeze protection or lower-range temperature control is critical.

Where Reliability

Meets Innovation

At Drexan, we’re redefining trace heating with innovative, high-performance solutions that keep critical systems operational—no matter the conditions.