Trace Heating for Food Processing

Trace heating is essential in food processing to ensure safe, efficient, and consistent production of food and beverages. Temperature control is critical for maintaining product quality, preventing contamination, and ensuring compliance with health and safety regulations.

Tailored Trace Heating Solutions for Food & Beverage Operations

At Drexan, we understand that Food and Beverage manufacturers have unique needs. Trace heating cables installed in food and beverage plants are often exposed to liquids that can degrade misapplied cable jackets over time. For example, chocolates and food oils can degrade a polyolefin cable jacket over time. Another common occurrence is damage to cables that is caused when sanitary components are removed, cleaned, and replaced back into process lines.

Drexan Energy Systems offers trace heating systems for the most challenging applications ensuring smooth operations, preventing costly damage, and maintaining regulatory compliance. We have the expertise to advise on the correct cable application and installation method to ensure long term reliable performance of the heat tracing system.

We’re redefining trace heating with innovative, high-performance solutions that keep critical systems operational—no matter the conditions.

Drexan HeatTracer cables and connection systems are:

- Able to serve the most demanding environments including hazardous and non-hazardous areas as well as areas where corrosive exposure may be of concern.

- Certified to CSA (CUS) and UL standards for use

throughout North America. - Suitable for both metal and non-metal pipes, tanks and vessels.

Hazardous locations are defined by the Canadian Electrical Code (CEC) section 18 and the National Electrical Code (NEC) as; those areas in which the potential for fire or explosion exists due to the presence of flammable gases or vapours and combustible dusts.

For the most current information and complete details pertaining to hazardous locations refer to the

Why Is Process Temperature Maintenance Important?

Prevent Freezing

Stop syrups, oils, and water from freezing in cold processing environments.

Maintain Temperature

Keep ingredients like chocolate and dairy from thickening or solidifying.

Ensure Hygiene & Safety

Heat tracing supports sanitation by maintaining CIP system temperatures.

Prevent Sugar Solidification

Avoid crystallization in molasses, caramel, and other sugar-based products.

Support Quality Control

Enable consistent results in fermentation, pasteurization, and drying.

Protect Equipment

Safeguard tanks and pipes from thermal damage or blocked flow.

Related Resources

Related Products

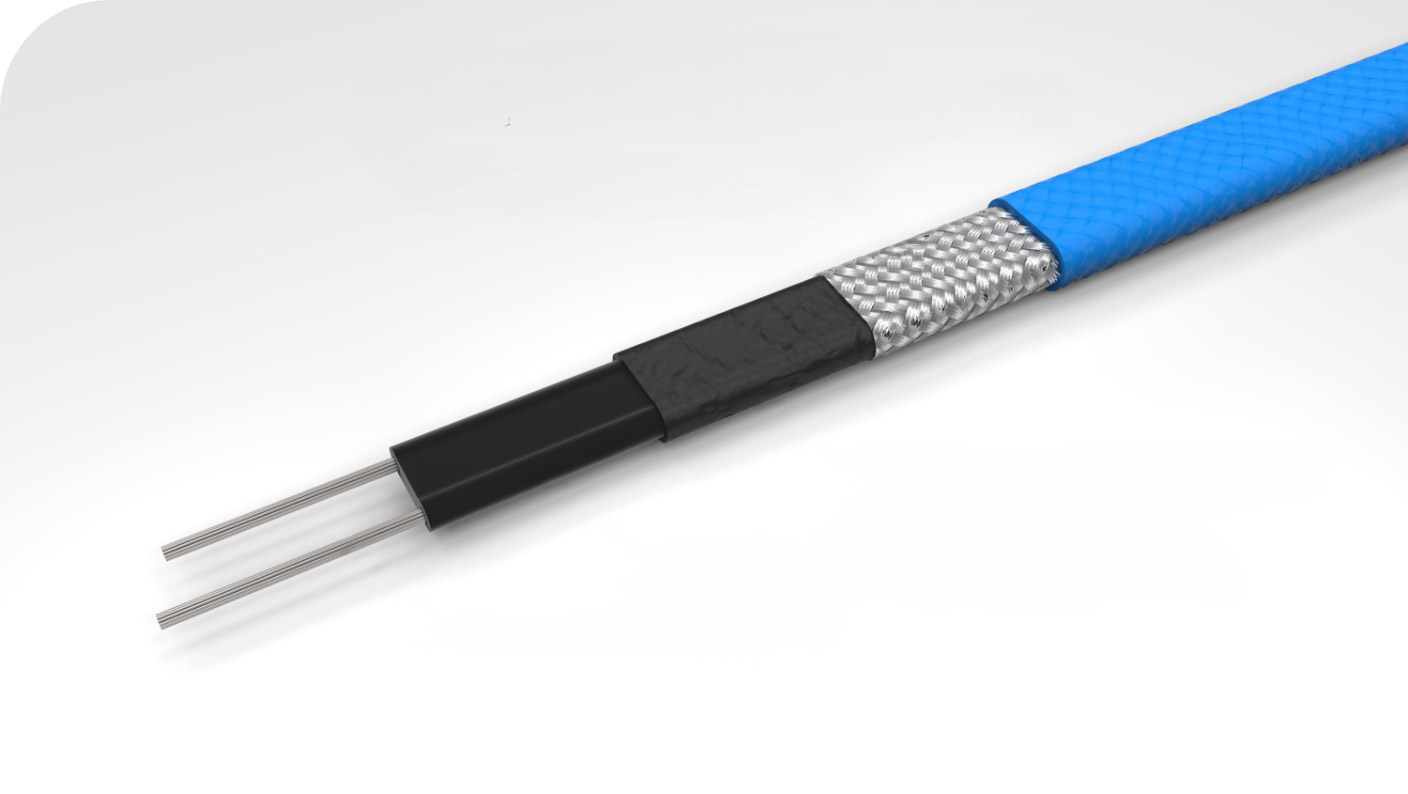

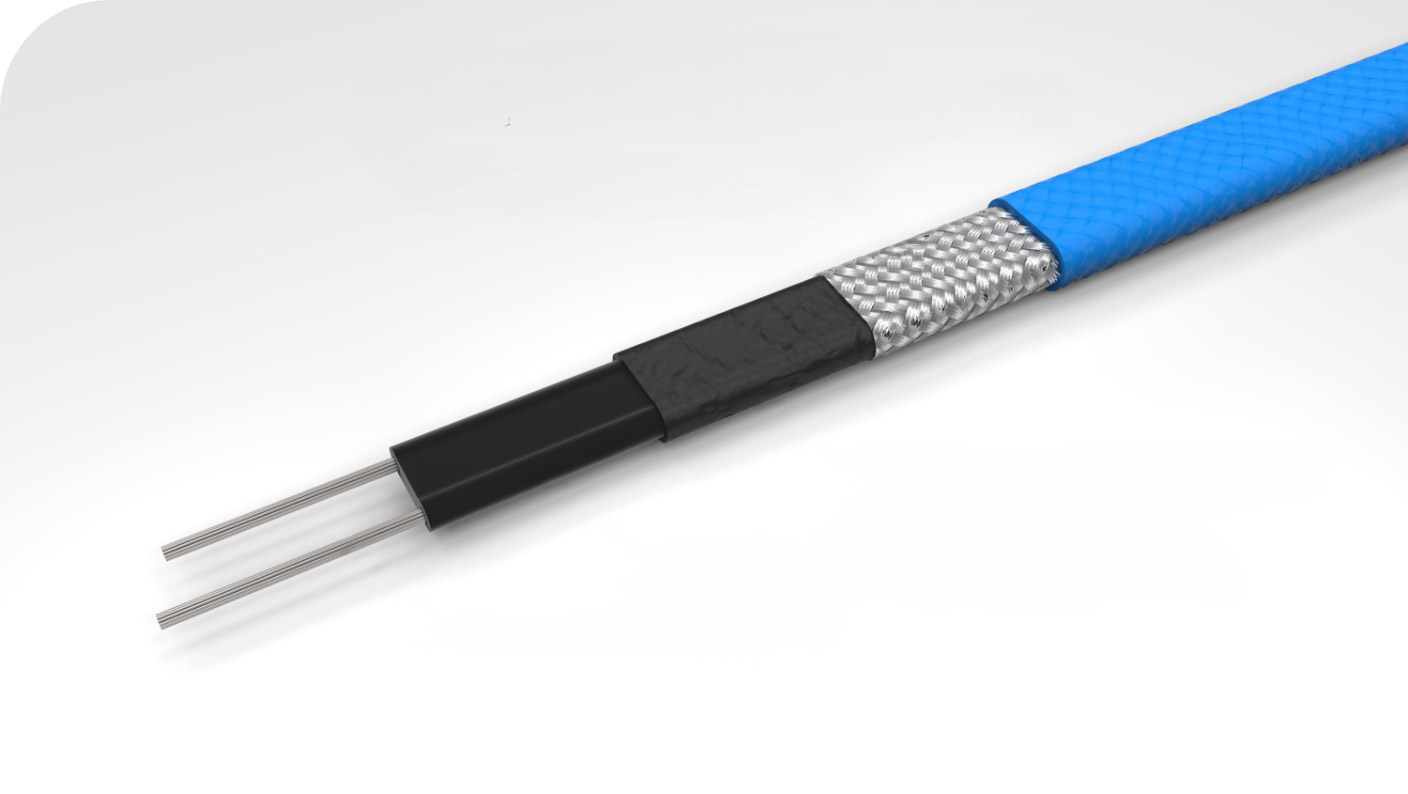

Trace Heating Cables

Need trace heating? We offer reliable, innovative solutions for freeze protection and temperature maintenance, with precise -0/+10% wattage tolerances.

AMIGA

Our family of high-profile components for installation with Drexan’s Self-Regulating Heating Cables.

Mechanical Thermostats

Thermostats ideal for applications where freeze protection or lower-range temperature control is critical.

Where Reliability

Meets Innovation

At Drexan, we’re redefining trace heating with innovative, high-performance solutions that keep critical systems operational—no matter the conditions.