Petrochemical, Chemical, Refining and Upgrading

Drexan Energy Systems offers trace heating systems for the most challenging applications ensuring smooth operations, preventing costly damage, and maintaining regulatory compliance.

We have extensive experience in engineering solutions for industrial applications. Drexan’s trace heating is crucial for Petrochemical, Chemical, Refining, and Upgrading industries because it ensures the reliable and efficient operation of process systems, particularly in environments where temperature control is critical.

Serious consideration must be given to:

- Hazardous areas

- Process temperatures

- Exposure temperatures

- Cable jacket sheath temperatures generated during cable warm- up

- Minimum design ambient temperatures

- Appropriate control and monitoring schemes, and

- Cable installation for ongoing maintenance and inspection.

Our design assistance and product capabilities ensure that the correct heating cable is applied, whether on a single line or on a green-field project with thousands of lines.

Drexan HeatTracer cables and connection systems are:

- Able to serve the most demanding environments including hazardous and non-hazardous areas as well as areas where corrosive exposure may be of concern.

- Certified to CSA (CUS), and UL standards for use

throughout North America. - Suitable for both metal and non-metal pipes, tanks and vessels.

Hazardous locations are defined by the Canadian Electrical Code (CEC) section 18 and the National Electrical Code (NEC) as; those areas in which the potential for fire or explosion exists due to the presence of flammable gases or vapors and combustible dusts.

For the most current information and complete details pertaining to hazardous locations refer to the Canadian and National Electrical Codes.

Related Resources

Zone Information Guide for a complete list of hazardous locations

Download NEMA ratings for a complete list of enclosure types

Design Worksheet to choose the right trace heating system

Why is High Temperature Maintenance Important?

Prevent freezing in lines

and equipment

Keep fluids above their freezing point to avoid blockages in pipes, valves, and equipment.

Maintain process temperature

Ensure fluids stay within optimal temperature ranges for efficient reactions and product quality.

Reduce corrosion and condensation

Minimize temperature swings that cause condensation and lead to internal corrosion.

Improve safety and compliance

Prevent hazardous pressure build-ups caused by cooled or solidified materials.

Enhance operational efficiency

Maintain steady flow and reduce the need for energy-intensive reheating processes.

Related Products

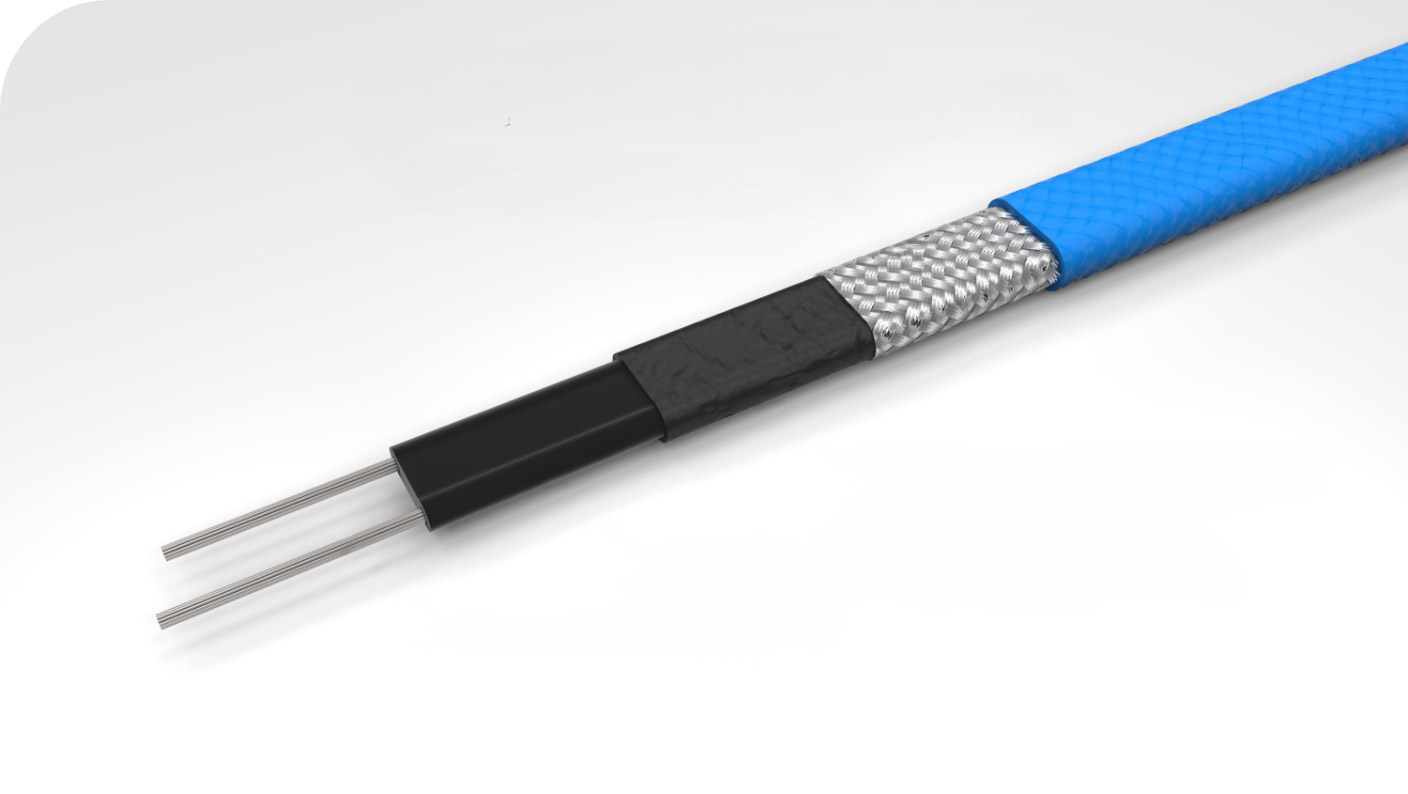

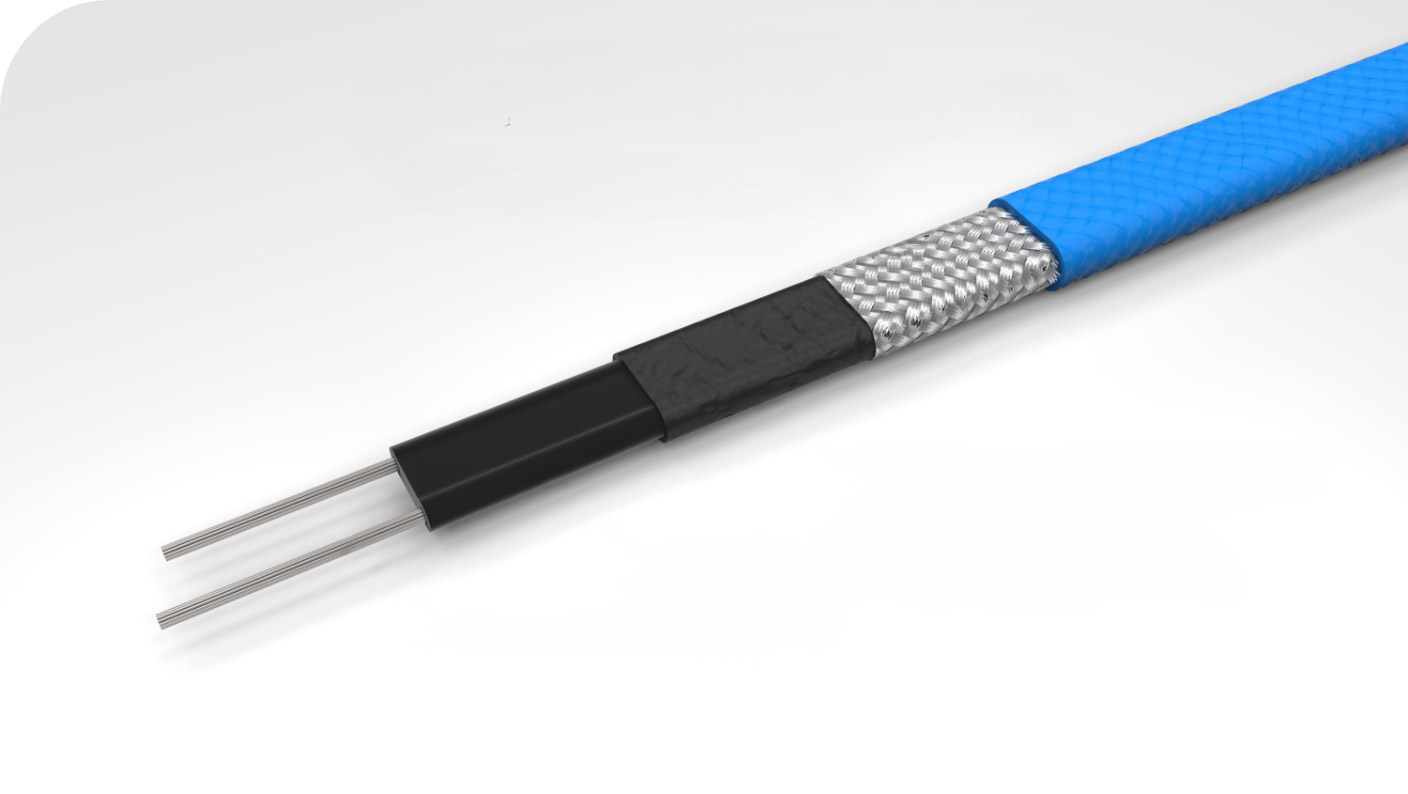

Trace Heating Cables

Need trace heating? We offer reliable, innovative solutions for freeze protection and temperature maintenance, with precise -0/+10% wattage tolerances.

AMIGA

Our family of high-profile components for installation with Drexan’s Self-Regulating Heating Cables.

Mechanical Thermostats

Thermostats ideal for applications where freeze protection or lower-range temperature control is critical.

Where Reliability

Meets Innovation

At Drexan, we’re redefining trace heating with innovative, high-performance solutions that keep critical systems operational—no matter the conditions.